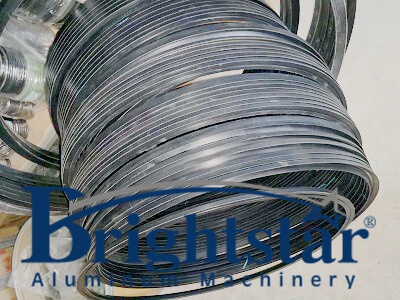

Aluminum extrusion press heating tube

Aluminum extrusion machine heating tube

Aluminum extrusion press heating tube

Heating tube for aluminum extrusion machine

It was also called extrusion press electromechanical heating pipe, annealed heater pipe, seamless electric heating pipe, high temperature resistance dry burning heating pipe.

The heating tube is made of heating wire in a seamless metal tube (carbon steel tube, titanium tube, stainless steel tube, copper tube), the gap is filled with magnesium oxide powder with good thermal conductivity and insulation, and the tube is shrunk and processed into Various shapes required by users. It has a simple structure, high thermal efficiency, good mechanical strength, and good adaptability to harsh environments. It can be used for the heating of various liquids and acid and alkali salts, and it is also suitable for the melting of metals with low melting points (lead, zinc, tin, pasteur).

Functional characteristics

Small size and high power: The heater is mainly a bundled tubular electric heating element. Fast thermal response, high temperature control accuracy and high comprehensive thermal efficiency. High heating temperature: The maximum design temperature of the heater is 850 ° C. The outlet temperature of the medium is average, and the temperature control accuracy is high. Wide application limitations and strong compliance: The heater can be used in explosion-proof or popular places, the explosion-proof grade can reach dⅡB and C grade, and the pressure can reach 20MPa. Long life and high reliability: The heater is made of extraordinary electric heating materials, designed with low external power load, and adopts multiple maintenance, which greatly increases the safety and life of the electric heater. Fully automatic control: According to the requirements, the heater circuit design can facilitate the automatic control of parameters such as outlet temperature, flow, and pressure, and can be networked with computers. The energy saving result is obvious, and the heat generated by the electric energy is almost 100% transferred to the heating medium.

Application

Suitable for heating air, oil, water, chemical media, hot stamping molds, molten salts, alkalis and low melting alloys. With high thermal efficiency, long service life, high mechanical strength, easy installation, safe and reliable.

1.Voltage and power (the voltage is determined according to the wiring method and the rated voltage; the power is determined according to the heating medium and size, and the sales staff can be consulted for details)

2.Pipe diameter (generally 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, etc.)

3.Unilateral length (tell whether the length of the fastener thread is included)

4.Does it contain fasteners, if with fasteners, what is the fastener size and thread length?

5.Center distance. (Generally, the pipe diameter is 8mm, the center distance is at least 30mm, the pipe diameter is 10mm, the center distance is at least 40mm, the pipe diameter is 12mm, the center distance is at least 50mm, the pipe diameter is 16mm, the center distance is at least 70mm, the pipe diameter is 20mm The center distance must be at least 90mm. The above data is for reference only.)

6.Appearance material selection: The main materials are 10 # carbon steel, SUS304, SUS321, SUS316L, stainless steel with coating (waterproof scale treatment), SUS310S (commonly known as: 2520), titanium tube, etc.

7.Material selection of electric heating wire: generally iron-chrome-aluminum wire, nickel-chrome wire (generally H140, 2080 resistance wire, etc.) The choice of these two depends on the customer’s working environment (temperature and vibration).