Aluminum profile anodizing clamp

Aluminum profile anodizing clamp

Aluminum profile anodizing clamp

Aluminum profile anodizing clamp

Quick anodizing clamp for aluminum profiles anodizing

An aluminum profile anodizing clamp, also known as the anodizing plier clamp, is an anodizing non-pneumatic clamp.

An anodizing non-pneumatic clamp is a manual device used to secure aluminum profiles during the anodizing process.

Anodizing non-pneumatic clamp, also known simply as a non-pneumatic clamp, is a type of clamp used in anodizing processes, it does not rely on pneumatic (compressed air) power for operation.

Instead, it may utilize mechanical, hydraulic, or manual mechanisms for clamping.

Unlike pneumatic clamps that use compressed air for actuation, non-pneumatic clamps rely on manual force for clamping and unclamping profiles.

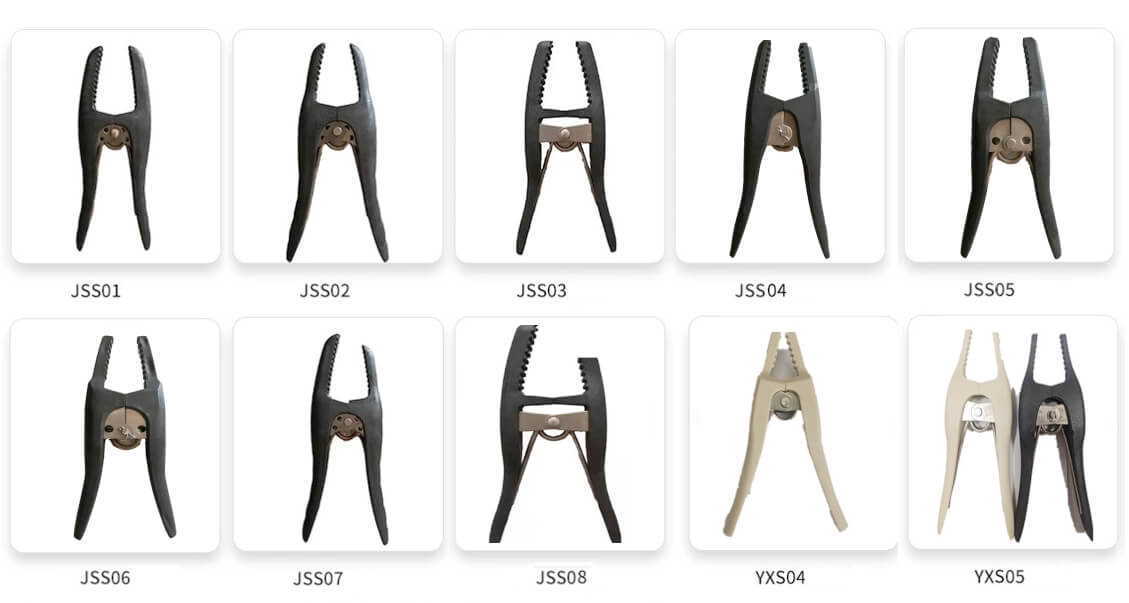

Anodizing Non-Pneumatic Clamps model

Anodizing quick clamp is one kind of fastener that replaces aluminum wire banding, which can save time, improve work efficiency, and reduce costs.

Anodizing quick clamp fixed profiles can be acid and alkali-resistant, have high-temperature resistance, and have high reusability.

It can be used up to 3000 times or more (normal use, more than one year) and the spring wire of the quick clamp is imported 316L spring wire, which is extremely durable.

Temperature resistance can be as high as 270℃.

Comparison between aluminum profile anodizing clamp and traditional aluminum wire racking

| NO. | Comparison Item | Anodizing Clamp | Aluminum Wire Racking |

| 1 | Safety | One time operation, no need to tighten rack again. Safe operation. | During the anodizing process, the workers are exposed to the odor emitted by strong acids and alkalis when tightening the rack.

Long-term work will cause physical discomfort to the workers |

| 2 | Jig mark waste | 2-3cm jig mark with anodizing clamp | 10cm jig mark with aluminum wire racking |

| 3 | Speed and efficiency | More than twice as fast as aluminum wire racking | The loading and unloading will be slow |

| 4 | Scope of application | Need different models for large and small section | Suitable for both large and small aluminum profiles |

| 5 | Tightening strength | Using a clamp to rack the aluminum material has greater force and uniform pressure | When jigging with aluminum wire, the force is uneven, resulting in different tightness |

| 6 | Color and anodizing film | The color and the anodizing film are more uniform | The color and the anodizing film are uneven. |

| 7 | Temperature resistance | Different types of clamps have different temperature resistance, so different types of clamps should be selected according to different processes. | Basically meets the requirements of the process |

| 8 | Conductive | The clamp is not conductive, conducts electricity by clamping the aluminum profile and the conductive rod when in use. | The conductivity is good, but it is easy to consume materials |

| 9 | Quality waste | Only when the clamp is loosened due to operating errors, will a piece of aluminum profile be scrapped due to quality problems. | If aluminum wire breaks loose, the entire rack of aluminum profiles will be burned and scrapped |

| 10 | Labor cost | The anodizing clamp requires 2 fewer workers per shift than the traditional process. | Traditional process requires more workers in each shift |

| 11 | Electricity Costs | Since the clamp is non-conductive, there is no problem of extra electricity consumption. | Since aluminum wire also consumes electricity when anodizing, every 1kg of aluminum wire used to rack aluminum will consume an additional 1 kWh of electricity. |

| 12 | Training cost | It only takes one week for each new operator to become familiar with the operation process, which results in low training cost. | It takes more than 1 month for each new operator to become familiar with the operation process, which results in high training cost |

| 13 | Human Resource | Solve the bottleneck problem of low production efficiency caused by the turnover of employees. | It is difficult to hire skilled operators and the turnover of employees is high |

| 14 | Service life | The normal use of the anodized clamp is about 1-2 years | Aluminum wire can only be used twice before scrap |

| 15 | Energy saving&ECO | The use of anodizing clamps can be reused for more than 3,000 times.

It is in line with the international low-carbon and environmental protection industry. |

The frequent recycling of aluminum wire is not suitable for the international low-carbon and environmental protection industry |

| 16 | Cost saving

Direct material cost Labor cost Quality loss cost Depreciation

|

Save more than 52% | Cost is high |

Features of aluminum profile anodizing clamp

Mechanical or Hydraulic Operation: Non-pneumatic clamps may use mechanical levers, screws, or hydraulic systems to apply clamping force to hold workpieces securely.

Manual Adjustment: Some no-pneumatic clamps may require manual adjustment for clamping pressure and positioning. This can involve turning screws or knobs to tighten or release the clamp.

Variety of Designs: Non-pneumatic clamps come in various designs to accommodate different applications and workpiece sizes. This includes toggle clamps, screw clamps, lever clamps, and hydraulic clamps, among others.

Durable Construction: Like pneumatic clamps, non-pneumatic clamps are often constructed from durable materials such as steel or aluminum to withstand the rigors of industrial environments.

Application of anodizing clamp

Aluminum profile anodizng clamp application

Advantages of anodizing clamp application

1. Cost-saving

The use of an anodizing clamp only requires 0.001 USD production loss each time.

The anodizing clamp can be used more than 3,000 times.

It can be used for more than one year.

If we use aluminum wire to fix aluminum profiles, aluminum wire cannot be reused up to 2 times, even if it can be used again after the recycling, and the loss cost is more than 25%.

2. Time-saving

The profile is fast fixed with an anodizing clamp.

It only takes 10 seconds for each loading, but if you use aluminum wire to fix the profile, the average loading time is more than 30 seconds.

(Furthermore, the data does not include the time required for further fixing during the anodizing process.

3. Work efficiency improving

Only two workers are needed during the whole process of using the anodizing quick clamp to fix the profile.

Because the clamp has good stability, it will no longer need manual fixing during the anodizing and lifting process.

With aluminum wire fixing profiles, the entire process requires four employees, because two of the workers have to fix the aluminum wire again during the anodizing process.

4. No Need for Compressed Air

Unlike pneumatic clamps, no-pneumatic clamps do not require a source of compressed air for operation.

This can reduce the complexity of the setup and eliminate the need for air compressors and associated maintenance.

5. Lower Operating Costs

Since they do not rely on compressed air, no-pneumatic clamps can be more cost-effective to operate in the long run, as they typically consume less energy and require fewer components to function.

6. Simplicity

Non-pneumatic clamps are often simpler in design compared to pneumatic clamps, which can make them easier to maintain and repair.

They may also be easier to operate manually without the need for complex control systems.

7. Suitability for Certain Environments

In environments where the use of compressed air is not practical or permitted, such as in clean rooms or hazardous areas, no-pneumatic clamps offer a viable alternative for securing workpieces.

In summary, an anodizing no-pneumatic clamp provides a reliable and cost-effective solution for securely holding workpieces during industrial processes, offering simplicity, versatility, and durability without the need for compressed air.